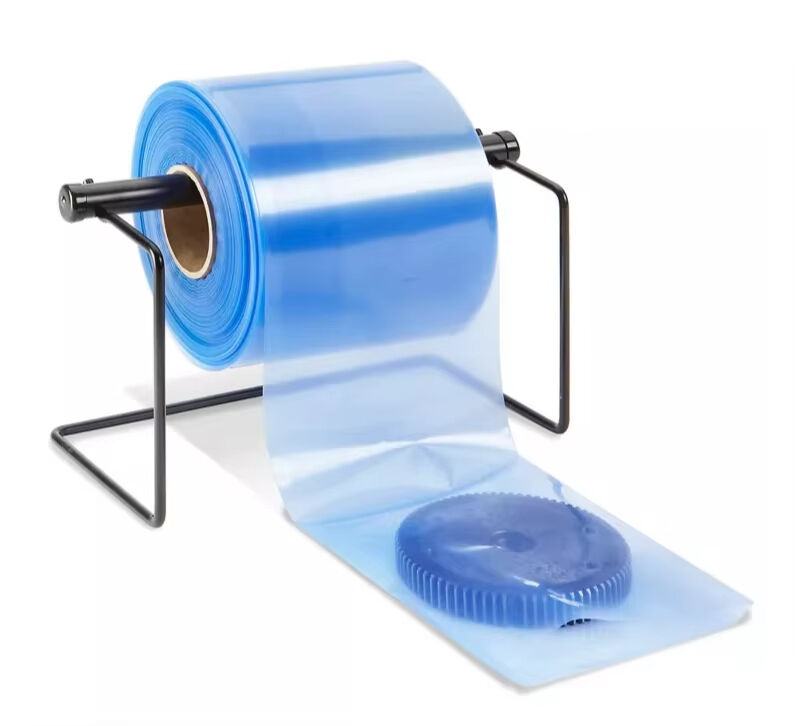

vci film for sale

VCI film for sale represents a cutting-edge solution in corrosion prevention technology, offering superior protection for metal products during storage and transportation. This innovative protective material incorporates Volatile Corrosion Inhibitors (VCI) that actively release corrosion-inhibiting molecules, creating a protective molecular layer on metal surfaces. The film is engineered with multiple layers of high-grade polyethylene that provides excellent mechanical strength while maintaining flexibility for easy application. Available in various sizes and thicknesses, VCI film effectively shields against moisture, salt, aggressive industrial atmospheres, and other corrosive elements. The technology works through a controlled release mechanism, where the VCI molecules vaporize and condense on metal surfaces, forming an invisible, protective barrier that prevents oxidation and corrosion. This advanced packaging solution is particularly valuable for industries dealing with precision metal components, automotive parts, aerospace equipment, and industrial machinery. The film's clear composition allows for easy visual inspection of packaged items without compromising the protective barrier. Additionally, it's environmentally responsible, being recyclable and free from harmful nitrites, making it a sustainable choice for modern industrial applications.