Customization and Technical Support

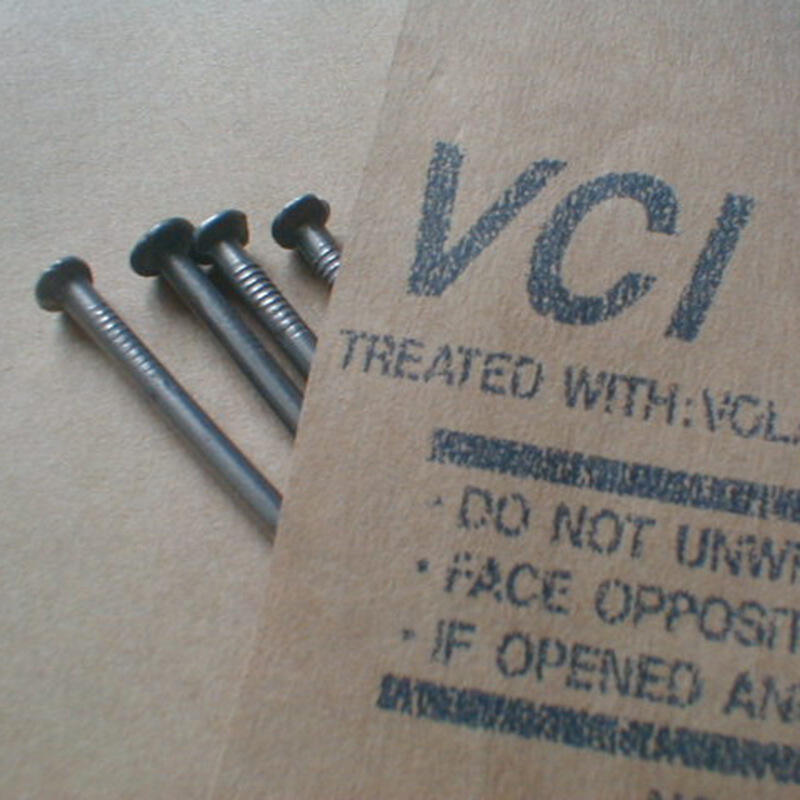

VCI bag manufacturers excel in providing tailored solutions that precisely match customer requirements. Their technical teams work closely with clients to analyze specific protection needs, considering factors such as metal type, environmental conditions, and storage duration. These manufacturers maintain extensive material libraries and formulation capabilities, allowing them to customize VCI concentrations and barrier properties for optimal protection in various applications. They offer comprehensive technical support services, including packaging design consultation, implementation assistance, and ongoing performance monitoring. The manufacturers provide detailed technical documentation, including test reports and usage guidelines, ensuring proper application and maximum protection effectiveness. Their engineering teams can develop custom sizes, shapes, and configurations to accommodate unique product dimensions and packaging requirements.