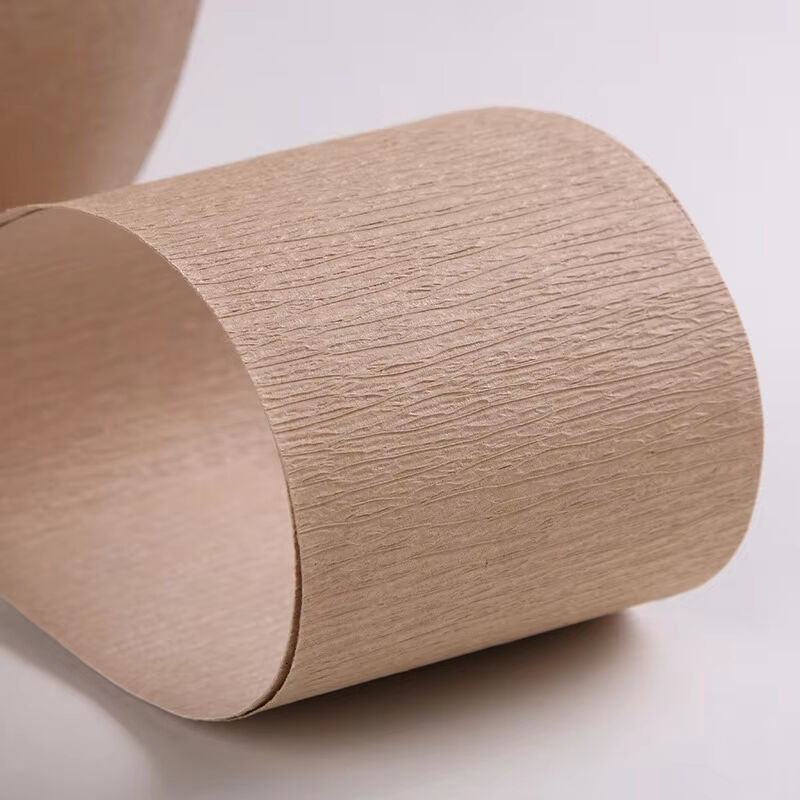

thick crepe paper

Thick crepe paper represents a versatile and durable material characterized by its distinctive crinkled texture and substantial weight. This specialized paper variant typically features a basis weight ranging from 90 to 140 gsm, making it significantly more robust than standard crepe paper. The manufacturing process involves a specialized creping technique that creates uniform micro-pleats throughout the material, resulting in exceptional elasticity and strength. The paper's unique structure allows for superior absorbency while maintaining its structural integrity, even when wet. This material exhibits remarkable stretch properties, capable of extending up to 140% of its original length without tearing. The surface texture provides enhanced grip and handling characteristics, making it ideal for various industrial and creative applications. The thickness and durability of this paper type make it particularly suitable for packaging delicate items, craft projects, and industrial applications where standard paper products would be insufficient. The material's inherent properties include resistance to tearing, excellent conformability, and the ability to maintain its shape after manipulation. These characteristics make thick crepe paper an essential component in sectors ranging from medical packaging to decorative arts, offering both functional benefits and aesthetic appeal.