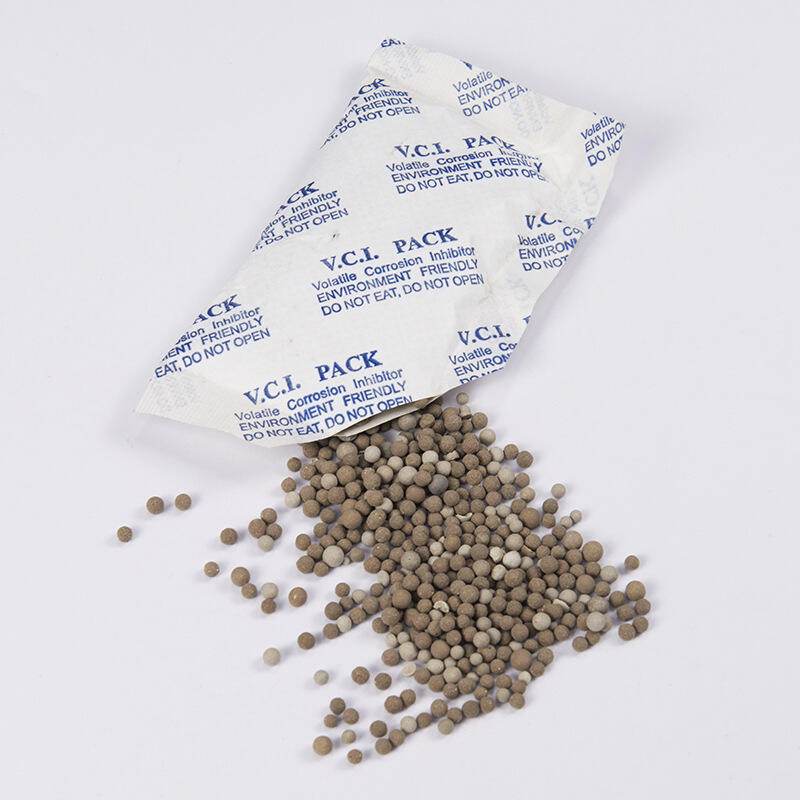

desiccant vci

Desiccant VCI (Volatile Corrosion Inhibitor) represents a cutting-edge solution in corrosion prevention technology, combining moisture control and active corrosion protection in a single product. This innovative solution works through a dual-action mechanism: the desiccant component actively absorbs moisture from the surrounding environment, while the VCI molecules create a protective molecular layer on metal surfaces. The technology operates by releasing protective vapor molecules that form an invisible, self-healing barrier on metal surfaces, effectively preventing rust and corrosion. This protective shield is particularly effective in enclosed spaces such as packaging, storage containers, and shipping units. The desiccant VCI system is designed to provide long-term protection for metal parts, equipment, and valuable assets during storage and transportation. Its effectiveness spans across various environmental conditions, maintaining consistent performance in both high-humidity and fluctuating temperature situations. The system is particularly valuable in industries such as automotive, aerospace, military equipment, and electronic components, where moisture and corrosion protection are critical requirements. The technology eliminates the need for traditional, often messy protective coatings or oils, offering a clean, dry, and environmentally conscious solution for corrosion prevention.